Progressive

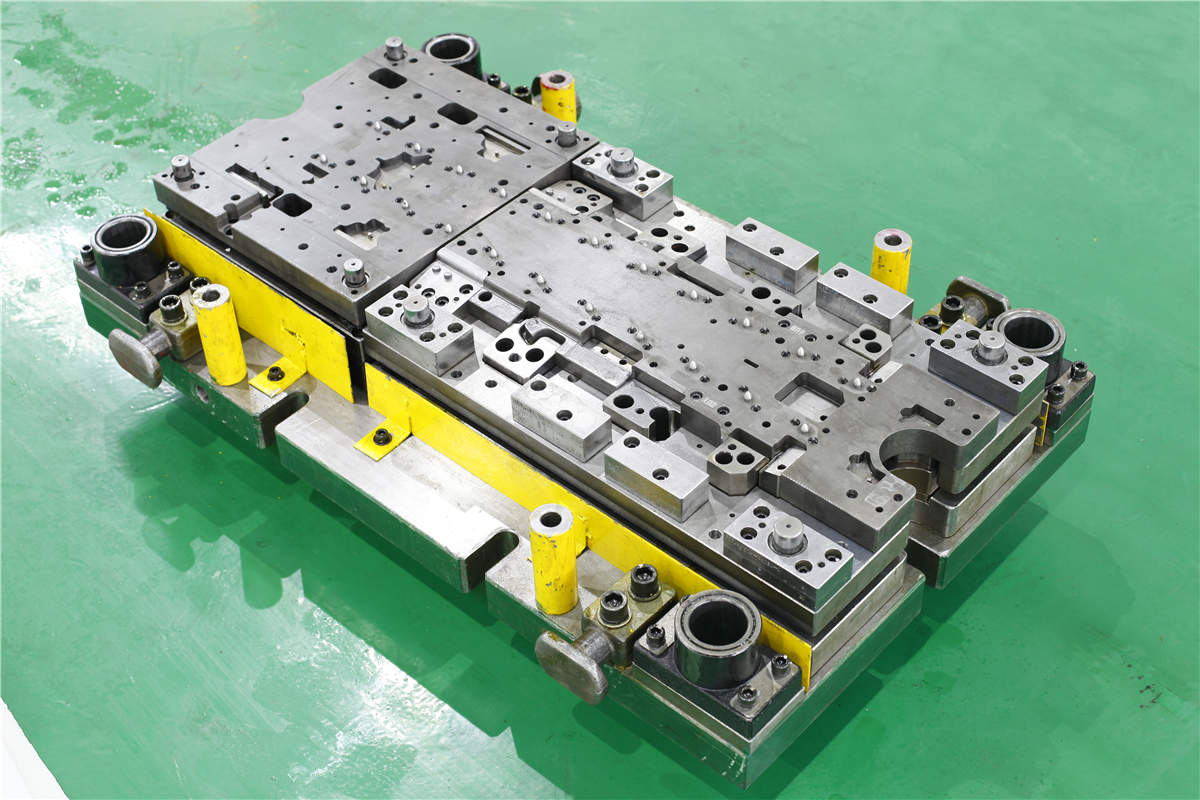

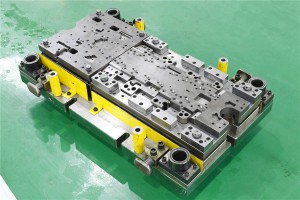

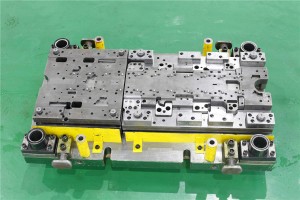

Tool type: Transfer tool

Process: 1500T x 6 stages

Tool Size: 1715mm x 775mm x 900mm

Tool Weight: Total Weight 21098kg

Tool Material Grade: Upper and Lower die shoe & blank holder: S50C

Forming plate, trim punch & cutting edge: SKD11 HRC58-60

Stripper plate insert, some forming block: HMD-5

Steel Treatment: Forming Draw Block: TD+Chroming

Upper Die: FCD550+Chroming

Standard Components: Main standard part are sourced from MISUMI, gas spring are .

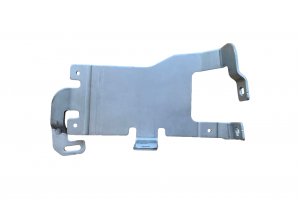

Stamping part material: CR210BH-GI50/50-U

SPM: 30

Cavity: R and L two part out

Complexity: Middle

◆Application: The tool applicated to automotive stamping part mass production.

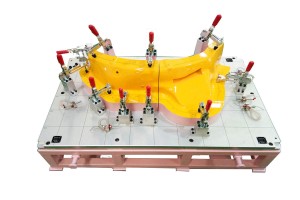

Press Machine: 2000T hydraulic press, 1200T Mechanical

Lead Time: 6 months

Background:

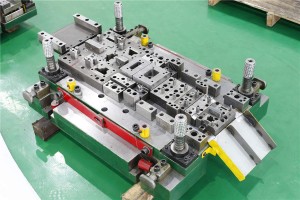

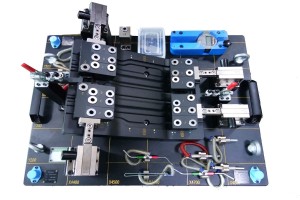

As we all known that gripper interference to transfer tool is a common issue, our designers will dynamically simulate for transfer tools after die design finished in order to avoid tool interference, shorten further tool maintenance and improve work efficiency. Besides, after tool is made, we will run real object simulation for gripper to pick up and transfer parts, by this way then check if any interference problem with transfer tool.

Advantage:

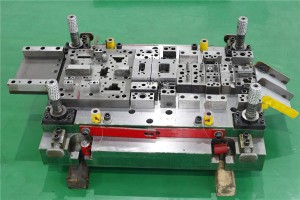

Professional Service: professional team to support our oversea customers, from stamping dies design review, timing report, buy off to home line tryout.

Faster Lead time: 16-17 weeks to provide the tool cut samples for transfer dies, 20-21 weeks to provide the 100% qualified samples to our customers.

Best Price for Progression tool, transfer tool and checking fixture.

If you are interested in transfer tool or have any other questions, please don’t hesitate to contact me, and we will be pleased to reply you.